It should be from two aspects. Firstly, the product. Secondly, the factory’s R&D, design, production and quality control capabilities.

What Kind of Grow Light is the Most Suitable Light for the Market?

- The type of light. The type of Fluence light bar is mainly used in cannabis cultivation.

In greenhouses, taking tomatoes as an example, the top cover and the fill-in are generally used.

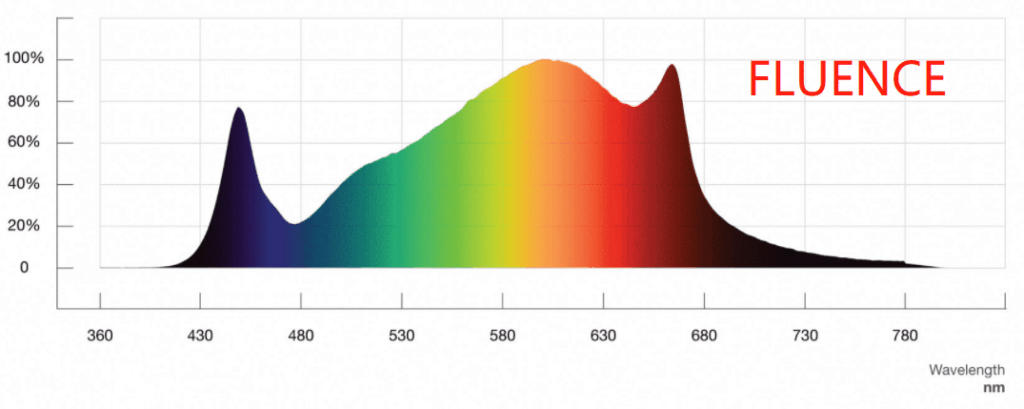

- Spectrogram. Fluence’s has been extensively verified by the market. It is also necessary to use Far Red, UVA, and UVB light appropriately and correctly, you can refer to the blog. Many growers complain that cannabis grows too high, so it is recommended that the blue peaks of light can be controlled. In the growth period, the blue light is adjusted higher. In the flowering period, the blue peak should be lowered.

- The output power of the light and PPE. PPF = output power x PPE. The outpower should be considered energy-saving, not the bigger the better. 631W and 800W are common. But the PPE is the higher the better without considering the price. 2.7 umol/j is of a leading level.

- The distribution of PPFD. It is recommended to pay attention to the value and distribution at the height of 6” and 12”. In the case of the same central value, a uniform PPFD distribution can bring higher THC and CBD production.

- LED. Choose a brand with Q90 certification. In this way, the maintenance rate of PPF can be bigger than 90% at 36000 hours.

- SMT. The quality of the solder paste and the void ratio has a great influence on the electrical performance and thermal conductivity.

- Glue. Because the humidity of the cannabis growth environment is very high, spray glue on the LED module to protect the LED and solder paste layer. Need to pay attention to the ability of this glue to resist sulfides and amides. You can refer to this article.

- Heat dissipation. The solder joint temperature of LED diodes and the temperature difference between the solder joint and radiator, the smaller the better.

- Driver. Get the certification and quality assurance period of the corresponding model used.

- IP rating. Because of the high humidity in the grow environment, the higher the IP level, the better the stability. Refer to article 1, article 2, article 3, article 4.

- Controller. One is the controller that comes with the light, which can only adjust the power manually. A single controller can control 100-200 lights to realize automatic control of power and switching time.

Manufacturing Ability for LED Grow Light

- Environment check according to 5S standard.

- Number and work experience of electronics, software, and structural engineers.

- The number of workers and SMT devices. How many have worked in the company for more than two years? Training and promotion system for them.

- Quality inspection system and process for before, during, and after.

- Main suppliers and quality assurance agreements.

- The general manager’s philosophy on product development, quality control, and cooperation, etc.

- Which customers are working with and are there any Japanese customers?

- What certifications does the factory have? Such as DLC, ETL, UL.