There 3 certifications of ETL, UL and DLC for LED grow lights. There are strict requirements in terms of LED diodes, efficiency, driver, etc.

Understand the requirements to be met to apply for UL from the 4 subjects

1.Sample Requirements for LED Grow Lights

2. Common design types of LED grow lights

3. Common structural requirements for LED grow lights

4. LED grow light test requirements

Sample Requirements for LED Grow Lights

- Model list (including model name, input voltage, current, power, frequency, installation accessories, whether inductive components, whether there is a lightning protection device, overall size, etc.).

- The circuit schematic diagram, PCB wiring diagram, PCB silkscreen diagram of the LED light board (wiring diagram and silkscreen diagram are provided separately).

- LED specifications (or list the rated parameters of the LED and the manufacturer model).

- List of safety components (such as drivers, connecting terminals, sensors, etc., listing models and UL file numbers).

- Detailed dimensional drawings (all parts are disassembled and provided).

- Installation instructions (English version).

- The maximum working environment temperature? Application environment (minimum requirement for LED grow light use environment Damp)

Samples generally require 2 for each model (all accessories need to be installed)

If there are more models, you need to provide detailed information before further evaluation.

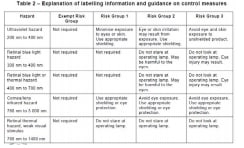

Common design types of LED grow lights

Single LED Module

The overall design type of the square box (generally with a fan)

Multiple LED Modules

Single LED Grow Light

Common structural requirements for LED grow lights

1.Complete construction review to UL 1598 or applicable end product standard. If the lamp housing or baffle is plastic, and these housings are exposed to sunlight or the light of plant lamps, the plastic used must have anti-UV parameters (that is, (f1)). If the environment where the lamp is used is a wet location, according to the requirements of UL1598 16.5.5 or UL 746C., the plastic used must have anti-UV parameters (that is, (f1)). If there are no wires, lamp caps, plugs, switches, connection terminals, etc., used on the lamps, these parts are exposed to sunlight or UV light, and wet location requirements are required.5. UL8800 8.3.1 is required to connect the input line of the power supply network, with one of the following connection methods: (a) According to UL1598, it can be connected with a metal hose. (b) It can be connected with a flexible cable (At least of the hard-service type, such as SJO, SJT, SJTW, etc. 4.5m long at most). (c) It can be connected with a flexible cable with a plug (NEMA specification). (d) It can be connected with a special wiring system

6. The minimum requirement of the application environment for plant growth lamps is damp location Damp and wet locations Horticultural lighting equipment shall be suitable for “damp” or “wet” location environmental requirements in the Standard for Luminaires, UL 1598. The determination for a “damp” or “wet” rating shall be based on the recommended installation environments in the manufacturer’s installation instructions. Damp location: 168 hours Humidity of 88 +/-2 percent at a Temperature of 32 +/-2C (89.6 +/- 3.6F) Wet location: Outdoor installation location directly exposed to rainwater.

Coating

Purpose: In order to improve the lighting effect of plants, the manufacturer removed the lens on the light board and changed it to coating; UL requirements: When there is only coating on the LED light board and no additional lens or housing, coatin needs to be evaluated separately as the housing;Coating problem 1. When the light board at the output end is located behind the power supply Class 2, it has the following requirements: A: dry & damp location, the light board is after class 2 (max 60Vdc) There is no requirement for Coating, just meet ordinary lamp test such as tide test etc.; B: wet location, light board after class 2 (max 30 Vdc) There is no requirement for Coating, and it is sufficient to meet common lamp test such as tide, rain test and so on; C: wet locations, the light board is after class 2 (max 60Vdc) There is no requirement for coating, and it can meet UL875 enclosure leakage current test and ordinary lamp test such as tide test, rain test, etc.; 2. When the light board at the output end is located behind the non-Class 2 power supply, the coating has the following requirements: A: QMJU2 material B: QMF22 material (if not need additional testing) QMJU2 material requirements: Need limited temperature (T1) The use environment needs to meet the lighting (indoor&outdoor) Thickness, minimum/maximum thickness is required Need to match the material of the light board (Mismatch requires additional testing)

Coating problem Glow wire end product test (Glow wire test)-If there is no QMFZ2 material, it needs to be tested End product arc resistance test (arc resistance test)-If there is no QMFZ2 material, it needs to be tested UV Exposure (1000H)-can be exempted with warnings Withstand voltage test-(2V+1000 or 500V) Adhesion And Abrasion Test UL 1598 Ball hit test-can be exempted with warnings UL1598 Barrier Strength Test UL1598 Coating description requirements in UL report: 1. Thickness 2. Manufacturer model 3. Installation process

Controller

The LED grow light has a controller, installed after the power dimming output, if the power dimming output is not class 2 output, the controller needs to be certified or separately certified; if the dimming output is clas 2 output, the controller needs to be certified.

LED grow light test requirements

1. INPUT MEASUREMENTS

(The measured input cannot exceed 110% of the rated value; the measured output cannot exceed the rated parameters of the power supply)

2.DIELECTRIC VOLTAGE-WITHSTAND TEST

(Withstand voltage test, see detailed explanation)-important

3.TEMPERATURE TEST (temperature rise test, see detailed explanation)

4.HUMIDITY CONDITIONING (Tide test, pass the withstand voltage after 168 hours)

5.BONDING CIRCUIT IMPEDANCE (ground resistance)

6.LOADING

7.RAIN

8.STRAIN RELIEF FOR FLEXIBLE CORDS

9.MOLD STRESS RELIEF

10.IMPACT

11.PHOTOBIOLOGICAL SAFETY ASSESSMENT

IP test requirements – (non-mandatory requirements)

Lighting equipment intended for use in an environment where it is exposed to excessive dust and water may, at the manufacturer’s requires, be additionally evaluated in accordance with the requirements of the Standard Degrees of Protection Provided by Enclosures (IP Code), IEC60529, and be marked with an IP Code.

When evaluated above, lighting equipment shall have a minimum rating of IP54 (protection for dust and water splashing).

When the manufacturer requires the bulb to apply for the IP environment,

Need IP test, at least IP54 level.

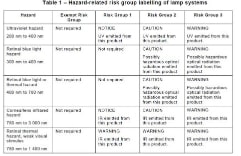

Photobiological Safety Assessment

1. Luminaires need to evaluate the band from 280 to 1400 nanometers in accordance with IEC62471 Wavelength: 280nm-1400 nm A) Ultraviolet hazard-280 nm to 400 nm; (UV hazard) B)Retinal blue light hazard-300 nm to 400 nm; C)Retinal blue light or thermal hazard-400 nm t0 780 nm; D) Cornea/lens infrared hazard-780 nm to 1400 nm; E) Retinal thermal, weak visual stimulus hazard-780 nm to 1400 nm. 2. The risk assessment results are Risk Group 0 (Exempt), Risk Group 1, or Risk Group 2. Three levels 3. If the evaluation result is Risk Group 3, it will not be accepted 4. If the lamp is a customer-replaceable light source, similar to a fluorescent lamp or HID, there is no need to assess photobiological safety. And it needs to be added on the nameplate and manual. 5. The nameplate of photobiological safety requires RG0 (Exempt), and no mark is required. RG1 and RG2 are marked with warning words in accordance with IEC/TR 62471-2 and placed where they can be seen after the lamp is installed. The instructions are repeated.

Understand the requirements to be met to apply for DLC from the 4 subjects

The V2.0 version is implemented on March 31, 2021.

Compliance Requirements

I. Structure: Lamps only, not including bulbs, light engines, and replacement parts

II. Type of light source: No light source type other than LED

III. Heat dissipation structure: The product cannot rely on externally provided active heat dissipation systems, such as liquid circulation, ducted forced ventilation, etc.

IV. Power supply: temporarily limited to AC products

Parameter requirements

| Parameters/Attributes/Units | Requirements | Request Type | Remark |

| Photosynthetic Photon Flux (PPF), (umol/s) | N/A | Only report data | The wavelength ranges is 400-700nm. 400-500nm, 500-600nm, 600-700nm need to be reported separately. |

| Far Red Photon Flux (PFfr), (umol/s) | N/A | Only report data | The wavelength ranges is 700-800nm. |

| Photon Flux(PFpbar), (umol/s) | N/A | Only report data (Optional) | The wavelength ranges is 280-800nm. |

| Spectral Quantum Distribution (SQD), (umol/s/nm) | N/A | Only report data | The wavelength ranges is 400-800nm. |

| Photosynthetic Photon Intensity Distribution (PPID), (umol/s/sr) | N/A | Only report data | The wavelength ranges is 400-700nm. |

| Photosynthetic Photon Efficacy (PPE), (umol/J) | ≥1.9umol/J, absolute tolerance -5%, (≥1.81 umol/J) | Required value/threshold | The wavelength ranges is 400-700nm. |

| PPhoton Efficacy (PEpbar), (umol/J) | N/A | Only report data | The wavelength ranges is 280-800nm. |

| PPhotosynthetic Photon Flux Maitenance (PFMp) | Q90≥36,000H | Required value/threshold | The wavelength ranges is 400-700nm. |

| pPhoton Flux Maintenance (PFMFR) | Q90 time | Only report data | (lm-80-15 / TM-21 or LM-84 / TM-28) The wavelength ranges is 700-800nm. |

| Driver Lifetime | ≥50000h | Required value/threshold | N/A |

| Fan Lifetime | ≥50000h | Required value/threshold | N/A |

| Warranty | 5 years | Required value/threshold | N/A |

| Power Factor (PF) | ≥0.9 | Required value/threshold | N/A |

| Total Harmonic Distortion, Current (THDi) | ≤20% | Required value/threshold | N/A |

| Safety Certification | UL8800 | Required value/threshold | N/A |

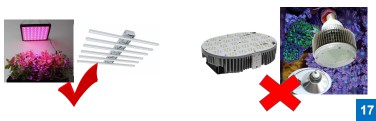

Differences with ordinary LED lighting products

I. Safety certification needs to be the UL8800 standard for LED grow lights.

II. The LM80 report of the lamp bead must be a test report based on LED grow lights.

III. The temperature test ambient temperature needs to be the highest operating temperature.

Update Cycle

The 24-month major revision cycle

DLC will maintain a 24-month period to revise the standards, mainly to improve the efficiency requirements of the products, and will eliminate 15% of the products with lower parameters each time.

The 12-month minor revision cycle

The smaller revision cycle will only focus on process and management improvements. Will not withdraw products due to efficiency restrictions.

Subsidy for DLC Certified LED Grow Light

In Quebec, Canada, you can get cash subsidies directly from Hydro Quebec when purchasing DLC-certified lamps.

| PPF range | Subsidy |

| <300 umol/s | 25 $ |

| 300-599 umol/s | 50 $ |

| 600-1199 umol/s | 100 $ |

| 1200-2399 umol/s | 200 $ |

| >2400umol/s | 300 $ |

Different cities have different subsidy institutions and policies. For example, some subsidize the corresponding kWh of electricity.