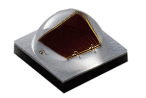

660nm can excite photosynthesis I and photosynthesis II, and promote the formation of chlorophyll B. For most plants, it is the most important wavelength. Someone calls it deep red, and someone calls it photo red. Now, we begin to talk about the 19 packaging processes of 660nm.

Chip Expansion

Because the chips provided by vendors are densely packed, in order to facilitate subsequent operations, we need to spread the chips.

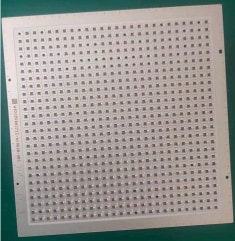

Fix Chip

Place chips after dispensing silver glue on the ceramic substrate.

Baking

Fix Zener

Baking

Wire bonding

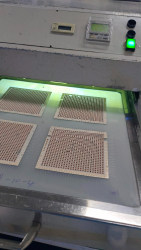

Molding

Baking

Stick UV Film on the Bottom of the Ceramic Substrate

Cutting

Cleaning

Baking

Remove UV Film

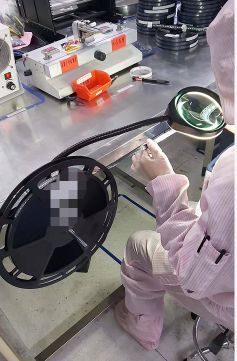

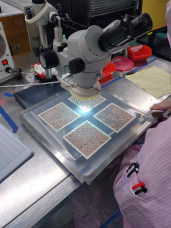

Check Appearance

Taking Off LED

Dehumidification

Test

Test the radiant power, wavelength, and voltage. Divide them into different tubes according to BINs.

Tape

Check Appearance