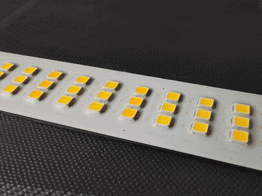

All LEDs must be soldered on the PCB. On the one hand, PCB is responsible for conducting electricity, on the other hand, it also has the function of heat conduction and heat dissipation. PCB consists of four parts: ink, copper foil, thermal conductive glue, and aluminum base.

Ink

If the brightness is pursued, the higher the reflectivity of the ink, the better. If the uniformity of light is pursued, it may be best to match the lens when the reflectivity is 85%. Also, need to consider the viscosity of the ink.

The reflectivity of the ink is related to the thickness of the ink. Generally, it is 22-28μm. If it is 30μm, the oil will explode when the V cut or V is worn. In order to avoid this situation, you can also spray two layers of ink, but this will increase the cost a lot.

The performance of each ink is different. For yellowing, it can be evaluated like this. At 260 degrees, bake for 30 seconds, it is OK if there is no obvious yellowing.

Copper Foil

The thicker the copper foil, the better the electrical and thermal conductivity.

Thermal Conductive Adhesive

The thermal conductivity of thermally conductive adhesives is poor, and its thermal conductivity is quantitatively different from other parts of the PCB.

Aluminum Base

Because aluminum is very soft, it is usually mixed with magnesium. The more magnesium, the harder the aluminum substrate, and it is not easy to warp. But it does not mean that the harder the better, because too hard will affect the punching.