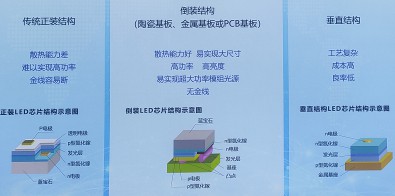

Samsung 301B | H, used extensively on LED grow lights. Its chip is flip. Samsung 301D used two formal chips. The chip of 660nm(Deep Red) is vertical. Compared with the formal chip, the voltage of the flip-chip is relatively low.

Two Major Factors Affect Chip Voltage

- The resistance of the chip. It is determined by the chip structure.

- The uniformity of current spreading. The diffusion of the current of the formal chip is generally made by increasing the fingers to make the current even. The fingers will block the light, so they must not be too large. But the flip-chip does not block the light and can achieve a relatively wide current expansion, so the voltage will be lower.

LED Flip-Chip Process Flow

- LED flip-chip process flowgraph substrate design and epitaxial structure design

- Extension customization and procurement

- Chip design (size, electrode shape, and distribution, bonding layer design)

- LED wafer process (ICP etching, metal electrode preparation, a passivation layer, bonding layer preparation)

- Flip-chip LED chip preparation (after grinding and polishing, cutting and splitting, semi-finished product testing, sorting)

- Flip keys and craftsmanship.

Material of the chip

The material of the formal chip and flip-chip is GaN. 660nm is a vertical chip, and the material is GaAs.