No matter how simple the vegetable garden is, maintenance should be carried out. In the soilless vegetable garden, the maintenance work mainly includes measuring and adjusting the concentration of the nutrient solution, and regularly cleaning the liquid supply system and the liquid storage tank.

Nutrient solution management

At present, there are many nutrient solution management programs in production. The type of vegetables to be planted, the size of the reservoir, the style of the garden, and personal preference all influence the choice of the grower. The author generally chooses the most time-saving plan. Of course, the growth of cooked vegetables is sometimes slightly affected. If the grower wants to better manage the nutrients and let the vegetables thrive, then they can refer to the following. Below we will introduce the management plan of the nutrient solution one by one according to the amount of work.

The easiest management solution

According to the fertilizer concentration recommended on the fertilizer package, calculate the water consumption of the whole bag or whole bag of fertilizer, and build a corresponding size storage tank. If the nutrient solution is too acidic or too alkaline, adjust the pH to a reasonable range. Vegetables that meet the harvest standards should be harvested in time. Pay attention to the water level in the liquid storage tank during the planting process, and beware of the lack of water and fertilizer for vegetables. This scheme can be used when green leafy vegetables are cultivated on floating plates. Of course, this scheme is also applicable to other systems. These systems need to be equipped with a large enough liquid storage tank, and the total amount of liquid storage should meet the moisture demand of vegetables. At present, Luis has grown a lot of vegetables with this scheme, and they are all in good condition. Of course, this scheme also has some shortcomings. For example, it is not suitable for the cultivation of vegetables with a long growth cycle, such as tomatoes, peppers, cucumbers and other fruits and vegetables, but if the grower wants to grow these vegetables, but also wants to save some energy, You can regularly replenish water in the pool, because fruits, vegetables, and vegetables require a lot of water.

Easier management solution

This solution is similar to the previous solution. When the amount of water in the liquid storage tank is insufficient, it needs to be replenished quickly. However, the nutrient solution will be over-diluted over time, and the plant may be short of fertilizer. This method is suitable for some fast-growing vegetables with low fertilizer content, such as sprouts, green leafy vegetables and certain herbs. Some fruits and vegetables can also use this scheme, but if the storage tank is too small, there is also a risk of lack of fertilizer.

(The seeds of coriander, arugula, basil and other vegetables can all be used to produce sprouts. Luis’ note)

More laborious management plan

In the process of soilless culture management, it is necessary to maintain the proper concentration of the nutrient solution. The usual method is: first irrigation and then adding fertilizer, and finally adjust the conductivity of the nutrient solution to the reference value. After the conductivity is stabilized at the reference value, acid (to decrease the pH) or alkali (to increase the pH) is used to adjust the pH (pH) of the nutrient solution. In fact, many things around us can adjust the pH. For example, adding grape juice or lemon juice can lower the pH of the nutrient solution, and adding baking soda can increase the pH of the nutrient solution.

In order to accurately adjust the conductivity of the nutrient solution, we need to prepare a conductivity meter, water-soluble fertilizer, a measuring cup, a pH meter, an acid regulator (such as lemon juice or baking soda) and a dropper.

Determine the initial conductivity of the nutrient solution in the tank after irrigation.

Mix the fertilizer, dissolve it and pour it into the tank.

When fertilizing, use a small amount several times to prevent overdose.

After adding fertilizer, stir by hand or use a water pump to circulate the water to fully mix the water and fertilizer. .

Add a small amount of fertilizer several times until the conductivity of the nutrient solution reaches the ideal value.

After the conductivity reaches the standard, measure the pH value of the nutrient solution.

Follow the safe operating procedures and avoid splashing acid or alkali on the skin.

When adding acid or alkali, use a small amount for many times.

After thoroughly stirring, re-measure the pH value of the nutrient solution.

Fine-tune the pH value of the nutrient solution until the target value is reached. Determine the initial conductivity of the nutrient solution in the tank after irrigation.

Mix the fertilizer, dissolve it and pour it into the tank.

When fertilizing, use a small amount several times to prevent overdose.

After adding fertilizer, stir by hand or use a water pump to circulate the water to fully mix the water and fertilizer. .

Add a small amount of fertilizer several times until the conductivity of the nutrient solution reaches the ideal value.

After the conductivity reaches the standard, measure the pH value of the nutrient solution.

Follow the safe operating procedures and avoid splashing acid or alkali on the skin.

When adding acid or alkali, use a small amount for many times.

After thoroughly stirring, re-measure the pH value of the nutrient solution.

Fine-tune the pH value of the nutrient solution until the target value is reached.

Nutrient solution renewal

To a certain extent, the electrical conductivity can reflect the nutrient content in the nutrient solution. Plants have high requirements for some nutrients and low requirements for some nutrients. Therefore, after a period of use, some elements in the nutrient solution begin to accumulate, while other elements are exhausted, causing nutrient imbalance in the nutrient solution. Large commercial farms often test the nutrient solution to obtain a nutrient content. Relevant data provide a reference for the next nutrient solution preparation. To this end, technicians not only need to rub a solid knowledge of chemistry, but also to fully understand the nutrient requirements of plants. Regularly renewing the nutrient solution can reduce the frequency of nutrient imbalances. When renewing the nutrient solution, the remaining nutrient solution in the system should be drained first, and the reconstituted nutrient solution should be injected. Crop types, environmental conditions, system types, fertilizers and water quality will all be able to update the number of nutrient solutions. Growers generally follow the following experience: When the amount of replenishing water is equal to the solvent in the reservoir, it needs to be updated.

For example, in a 152L pond, the daily evapotranspiration (including plant transpiration and natural water evaporation in the pond) is 19L. In order to offset the impact of evapotranspiration, growers need to add the same amount of water to the pond every day. After 8 days, the growers injected a total of 152L of water (8 days×19L/day = 152L). At this time, the total amount of water supplemented was equal to the volume of the storage tank. In this case, the grower needs to update the nutrient solution every 8 days.

Using special fertilizer for hydroponics and following the fertilizer application method can reduce the number of updates. The old nutrient solution obtained during the renewal should not be wasted. It can be used as water for potted plants, seedbeds, grassland and woodland. Traditional vegetable gardens can use the nutrient solution, plant residues and substrate used in soilless vegetable gardens to turn waste into treasure.

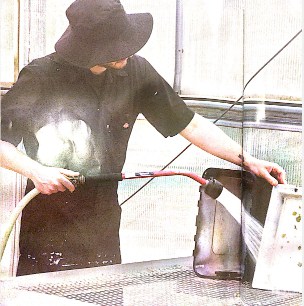

Cleaning and disinfection of nutrient solution system

There are many medicines on the market that can be used to clean and disinfect soilless vegetable gardens. Among them, the cleaning agent is used daily. Of course, some planting enthusiasts will also use other cleaning agents, such as bleach (concentration 3.5~3.6g/L), isopropanol (purity not less than 70%) and hydrogen peroxide (purity not less than 3%, when using high -Concentration of hydrogen peroxide, clean and disinfect the vegetable garden in strict accordance with the safety regulations on the outer packaging label of the bottle.

Before cleaning, remove the old base and plant residues in the tank.

The cleaning effect is best when the water tank is wet, otherwise it is difficult to remove dirt and plant residues.

If conditions permit, remove the water pump and sand head before cleaning the reservoir.

Remove plant debris by cleaning the seedling tray.

Most vegetable gardens use dishwashing liquid.

Use a sponge to gently scrub the culture tank to prevent scratches

Use a brush to thoroughly clean the residual fertilizer in the water pump and on the wires at the bottom of the pool.

Finally, wipe or air dry these parts.